1993---Set up

(One of the earliest extrusion mould pioneers in China)

1996---Hongda Plastic Mould Co., Ltd (PVC profile mould)

2002---Research and develop PVC WPC & PE mould

2003---Gain ISO9001(2000) & Sales exceed 5 million yuan

2004---Research PVC foam board

2005---Sales exceed 10 million & New factory(15000m2)

2007---Set up Shanghai eko Mould Co., Ltd

2008---Sales exceed 20 million yuan

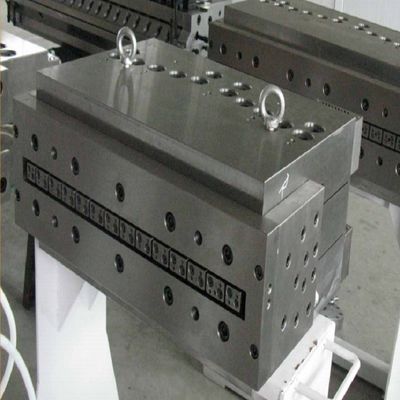

Polished and Electroplated 700mm CPVC WPC Hollow Door Panel Extrusion Mould Exporter

Product Details:

| Place of Origin: | Shanghai, China |

| Brand Name: | Eko |

| Model Number: | 700 width |

Payment & Shipping Terms:

| Minimum Order Quantity: | 1 set |

|---|---|

| Price: | $6,000.00 - $7,000.00/sets |

|

Detail Information |

|||

| Shaping Mode: | Extrusion Mould | Product Material: | PVC WPC |

|---|---|---|---|

| Product: | Hollow Door Panel | Product Name: | WPC Door Panel Mould |

| Mould Material: | 3Cr17 | Application: | Household Product Mold |

| Color: | Silver | Surface Treatment: | Polished Ang Electroplating |

| Size: | 700.800.900 Wide | Runner: | One |

| Cavity: | One | Keyword: | WPC Door Mould |

| Plastic Material: | WPC | ||

Product Description

Specifications

Die head | ||

Name | WPC Door panel mould | |

Size | 700mm | |

Delievry time | 45 Working days | |

Material | 3Cr17 | |

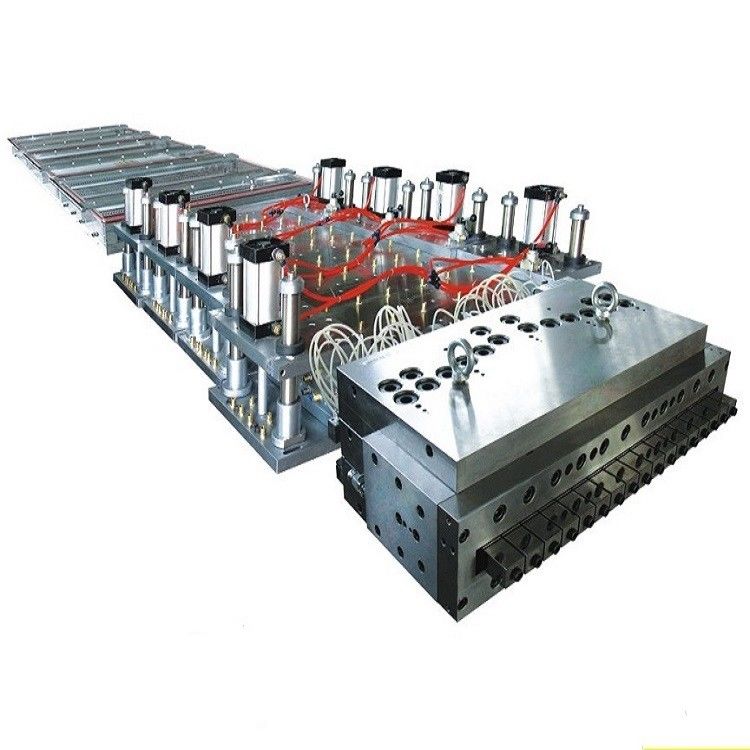

Calibrator | ||

Length | 500mm x 3 | |

Height adjustment | Air/Oil - cylinder | |

Cooling | Transverse circulating water cooling | |

Vacuum | Vacuum chamber formed by upper and lower boards | |

Screw | Stainless steel screw | |

Water tank | ||

Length | 2000mm x 1 | |

Cooling | Water cooling | |

Vacuum | Vacuum is formed by pumping | |

Screw | Stainless steel screw | |

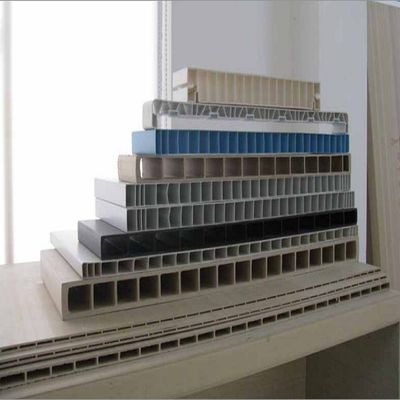

The Advantages of WPC

1. It is similar to wood appearance, but which has much better dimensional stability than wood.

(no cracks, warpage, no wood knots, twill)

2. It can be made into various products by adding colorant, laminating or compositing surface layer. Its hardness is higher than plastic. And its service life is longer.

3. It has the secondary processability similar to wood and the processing formability of plastics.

4. Anti-moth, anti-rat bite, acid and alkali resistance, corrosion resistance.

5. The products can be recycled and reused, which is friendly to the environment.

6. Wood-plastic composites are widely used because of their dual properties of wood and plastics.

Finished Product Samples

Enterprise Strength

We have three companies respectively in Huangshi, Wuxi and Shanghai.

OUR BRAND | ||||||

Development 1993--2018

2009---Research foam board crust technology 2016---Spread new product & technology of wall pane

2010---Produce wide board products 2017---Set up (EKO)Shanghai Yuhao Plastics Co., Ltd

2013---Set up joint-venture in outer Mongolia 2017---Set up (EKO) Wuxi Jiuke Mould Co., Ltd

2013---Sales exceed 50 million yuan 2017---Sales exceed 80 million yuan

2014---Foreign trade sales exceed 50 million yuan 2018---Unified use the brand---EKO

Huangshi Hongda Plastic Mould Co., Ltd | ||||||

(EKO)Huangshi Hongda Plastic Mould Co., Ltd, located in Huangshi, the City of Mould, which is the leading enterprise in the mould industry. And its annual output can achieve 1,500 sets of mould.

Wuxi Jiuke Mould Co., Ltd | ||||||

Wuxi Jiuke Mould Co., Ltd

(EKO) Wuxi Jiuke Mould Co., Ltd, specializing in

sheet and board mould and hollow door panel mold, which has the annual output of

300 sets of

mould.

Shanghai Yuhao Plastics Co., Ltd | ||||||

(EKO)Shanghai Yuhao Plastics Co., Ltd

A trading company based on Hongda and Eko mould company, which has a wide range, good quality, reasonable prices and stylish designs. Our products are extensively used in many different fields and industries.

Our products are widely recognized and trusted by users and can meet continuously changing economic and social needs.

We welcome new and old customers from all walks of life to contact us for future business relationships and mutual success!

Certifications

As a professional extrusion mould manufacturer with years of experience accumulation, we have created our own unique and perfect theory of extrusion integrated system. We are in the leading level in the filed of extrusion mould and obtain more than 10 national patents.

Corporate Culture

OUR CUSTOMERS, OUR FRIENDS

cities.

In the world, our products are exported to over

40 countries and districts.

We are proud to have friends all over the world.

Professional Technology

We provide the " turn-key-project " for the clients from material formula, operation technique,

extruder type selection to mould technique.

Mould Testing & After-Sales Service

Mould test is one of the most important element of the quality guarantee. We have a testing center and six advanced extrusion lines. Simulation in extrusion production testing offers guarantee for the mould before delivery, shorten testing time in your factory and help you to reduce the cost.

Our experienced technicians will give you the best service. We promise: In China, 360 days guarantee period, sending perfect service to your factory within 48 hours.

Vision: To be the top of extrusion mould manufacturer

Spirit: Professional, Efficient, Faithful

Style: Fast, Exact, Constant

NON-FUMIGATION WOODEN CASES

1. Do you charge for the product samples of the mould?

We provide free samples ,but the freight charges need customers pay.

2. Do you offer other products besides extrusion mould and parts ?

Yes. Besides extrusion mould and parts, We also offer extrusion products, such as pvc profiles, wpc door and frame, wall panel, spc & wpc flooring and so on. What's more, we offer chemical material and additives, extrusion machinery and parts and other equipment as well.

3. How about payment term ?

30% deposit before production and 70% balance payment before shipment

4. How about the production time ?

45 working days after the down payment reach our bank account and all the documents and drawings for production confirmed with signature.(The time does not include the mould trial in China)