Customized Voltage PVC Door Making Machine for Your Business

Product Details:

| Place of Origin: | Shanghai, China |

| Brand Name: | EKO |

Payment & Shipping Terms:

| Minimum Order Quantity: | 1 set |

|---|---|

| Price: | $70,000.00/sets 1-2 sets |

| Packaging Details: | Wrapped with film then packed by standard export wooden pallets or wooden boxes. |

|

Detail Information |

|||

| Condition: | New | Plastic Processed: | WPC |

|---|---|---|---|

| Application: | Door Panel | Screw Design: | Double-screw |

| Twin Screw Type: | Conical Twin Screw Extruder | Screw Material: | 38CrMoAlA |

| Screw Diameter (mm): | 92/188mm | Screw L/D Ratio: | 33:1 |

| Screw Speed (rpm): | 34.7 Rpm | Showroom Location: | None |

| Voltage: | Customized | Dimension(L*W*H): | 5750*1650*2760mm |

| Power (kW): | 110 | Weight: | 9000 KG |

| Warranty: | 1 Year | Key Selling Points: | Good Quality,competitive Price,experienced Support |

| Applicable Industries: | Manufacturing Plant, Construction Works | Video Outgoing-inspection: | Provided |

| Warranty Of Core Components: | 1 Year | Core Components: | Other |

| Machinery Test Report: | Provided | Product Name: | WPC Hollow Panel Production Line |

| Processing Type: | Exturding Machine | Usage: | Door |

| Raw Material: | Wpc | Capacity: | 450 ~ 500 Kg/h |

| Keywords: | Turn-key Project | After-sales Service Provided: | Video Technical Support |

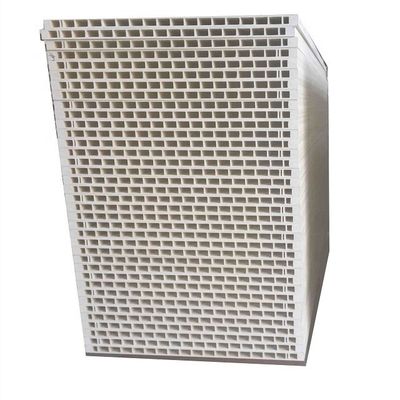

| Product Type: | Extrusion Production | Final Product: | WPC Door |

| Color: | Customers' Require | Marketing Type: | Hot Product |

| Port: | Shanghai Port | ||

Product Description

Wood Plastic Composite Door Panel Extrusion Line

Wood Plastic Door Panel Extrusion Line | ||||||||

Equipment List | Auxiliary Equipment List | |||||||

1 | 92/188 Conical Twin Screw Extruder | 1 | HL500/1000 Mixer | |||||

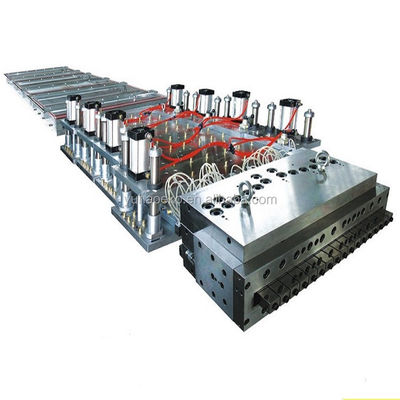

2 | PVC Wood Plastic Door Panel Mould | 2 | PS700 Crusher & 700 Grinding machine | |||||

3 | YFD1000 Vacuum Calibration Table | 3 | KHAW-50D Air cooling chiller system with water pump | |||||

4 | YFY1000 Haul-off Unit | 4 | Door panel hot stamping machine | |||||

5 | YFQ1000 Cutter | 5 | Door locking hole drilling machine | |||||

6 | YFF1000 Stacker | ps: custom choose if any need | (Custom choose these ) | |||||

Extrusion System

Hot Stamping Machine

Door locking hole drilling machine

Enterprise Strength melt blown fabric machine for face mask

We have three companies respectively in Huangshi, Wuxi and Shanghai.

(One of the earliest extrusion mould pioneers in China)

1996---Hongda Plastic Mould Co., Ltd (PVC profile mould)

2002---Research and develop PVC WPC & PE mould

2003---Gain ISO9001(2000) & Sales exceed 5 million yuan

2004---Research PVC foam board

2005---Sales exceed 10 million & New factory(15000m2)

2007---Set up Shanghai eko Mould Co., Ltd

2008---Sales exceed 20 million yuan

2010---Produce wide board products

2013---Set up joint-venture in outer Mongolia

2013---Sales exceed 50 million yuan

2017---Set up (EKO) Wuxi Jiuke Mould Co., Ltd

2017---Sales exceed 80 million yuan

2018---Unified use the brand---EKO

Huangshi Hongda Plastic Mould Co., Ltd | ||||||

(EKO)Huangshi Hongda Plastic Mould Co., Ltd, located in Huangshi, the City of Mould, which is the leading enterprise in the mould industry. And its annual output can achieve 1,500 sets of mould.

Shanghai Yuhao Plastics Co., Ltd | ||||||

(EKO)Shanghai Yuhao Plastics Co., Ltd

A trading company based on Hongda and Eko mould company, which has a wide range, good quality, reasonable prices and stylish designs. Our products are extensively used in many different fields and industries.

melt blown non woven fabric melt blown

Our products are widely recognized and trusted by users and can meet continuously changing economic and social needs.

OUR CUSTOMERS, OUR FRIENDS

melt blown non woven fabric melt blown

In the world, our products are exported to over 40 countries and districts.

We are proud to have friends all over the world.n

Testing & After-Sales Service melt blown non woven fabric melt blown filter for face mask

Test is one of the most important element of the quality guarantee. We have a testing center and six advanced extrusion lines. Simulation in extrusion production testing offers guarantee for the machine before delivery, shorten testing time in your factory and help you to reduce the cost.

Our experienced technicians will give you the best service. We promise: In China, 360 days guarantee period, sending perfect service to your factory within 48 hours.

Professional Technology

We provide the " turn-key-project " for the clients from material formula, operation technique,

extruder type selection to mould technique.

Vision: To be the top of extrusion mould manufacturer

Spirit: Professional, Efficient, Faithful

Style: Fast, Exact, Constant

Wrapped with film then packed by standard export wooden pallets for extruder and wooden boxes for moulds.

1. What kind of service can we expect from your side during this special period of pandemic ?

We all are trying our best to shorten the delivery time, and we'd love to offer some free medical supplies to help you fight against it. Regarding to our machinery, we are offering on line inspection test and on line instructions to help you install and start up the machinery.

2. What is delivery time of machinery and how about the payment terms ?

It will be different according to different model machines, usually for small ones need 45 working days. And the payment term is 50% as down payment and 50% before delivery.

3. What is your main business scope ?

As a trading company, we offer whole package solution of profile extrusion machinery and extrusion product such as door panel, UPVC profiles,WPC foam board, SPC flooring, wall panels, PP board, PE decking and so on.

4. Do you charge for the product samples of ?

We provide free samples ,but the freight charges need customers pay.